Laser marking and engraving on tools

The tool industry was one of the first to use laser marking. On tools, we mark identification codes for traceability, logos, and size and function information.

Since each tool has a precise function, the laser marking process such as engraving cannot change the geometry of the tool even to the slightest degree.

Markings are not raised, very visible, and usually be black. Verification of the marking is another fundamental step as the value of the tool gets higher.

There is a vast array of tools: milling cutters, drill bits, inserts, circular blades and discs, and band saws, just to name a few. We specialize in these applications, designing and developing different laser marking systems over the years.

The LASIT story started with a laser marking project made for ISCAR in the ‘90s. Today, they are still our clients and our best partners. We have gained enormous experience in this field, with 27 different laser systems made for the various applications of this very extensive and very challenging industry.

Which metals are suitable for laser marking of turning and milling tools?

Titanium and its alloys are ideal for laser marking due to their excellent strength-to-weight ratio and corrosion resistance. These materials can be precisely marked without compromising their structural integrity, making them perfect for high-performance tools.

High-Speed Steel (HSS) is valued for its ability to cut at high speeds without losing its hardness. Laser marking on HSS ensures precise and durable identification marks that can endure the high temperatures and stresses encountered during machining processes.

Stainless steel is a popular choice for laser marking because of its durability and resistance to rust and staining. Laser marking on stainless steel produces clear, permanent marks that can withstand harsh environments, essential for reliable tool identification.

Tool steel is known for its hardness and ability to retain a sharp edge, which is crucial for cutting tools. Laser marking on tool steel provides durable and legible marks, ensuring traceability and easy identification of tools in demanding applications.

Picosecond Laser Marker

Precision tooling: cutters, drill bits and inserts

The most suitable laser for marking tools is the active Fiber optic laser. The marking process for steel tools is generally annealing: the laser heats the surface of the tool locally, generating an oxide layer, which produces an impalpable black.

In the case of carbide or dark coated materials, it is possible to obtain white, impalpable and high-contrast marking by varying the parameters.

DataMatrix or QR-code marking verification

To ensure the traceability of tools, more and more manufacturers are marking tools with a Datamatrix or QRcode code, containing the logo and functional data.

With a vision system, we are able to centre marking, read it and verify its qualities according to reference standards.

The vision system: depending on the size and geometry of the part to be marked, the vision system can be either TTL (Through The Lens) or side-view.

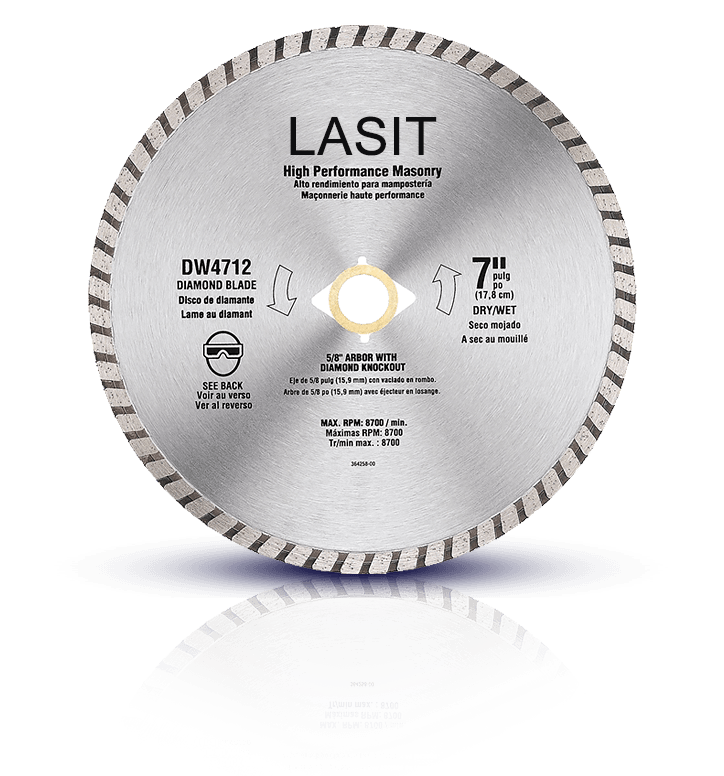

Grinding wheels and blades

These types of tools are very versatile in terms of application. They can be natural or coated using different treatments.

They can for example be diamond coated – a process necessary to increase their cutting capacity and wear resistance – or else painted to protect them from corrosion.

High-visibility, durable marking is re-quired for these types of products. The most suitable type of laser is our FiberFly, the latest generation laser with active Fiber optic source.

Grinding wheels, blades and discs can be very different sizes. LASIT has developed special solutions to facilitate their handling and marking.

The same system can mark blades and discs with dimensions ranging from 50 to 600 mm. To increase productivity, it is possible to automatically mark dozens of parts simultaneously using palletized systems.

To facilitate the handling of large blades, systems with external loading and ball tables have been created for blade sliding inside the marking compartment.

Our Advantages

| Sole supplier | No intermediary, from design to realization |

| Interface | PROFIBUS protocols, PROFINET and PROFIsafe |

| Integration | Integrations with MES / ERP systems |

| Industry 4.0 | Business database interaction for industry 4.0 |

| Vision system | Automatic centering, 2D code verification and grading, OCR recognition |

| Laser system | For every application and integration in production chains |