LASER CUTTING AND ENGRAVING

METAL

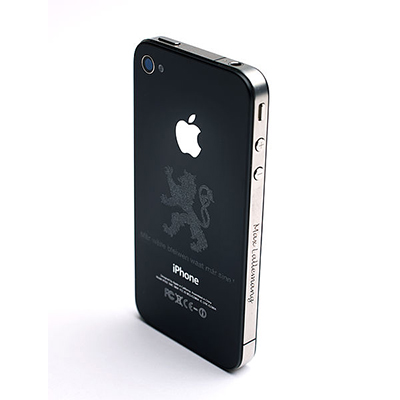

Laser machines have been serving customers internationally for many years, especially when it comes to the laser marking and laser cutting of metals in Middle East. Various types of metals such as aluminum, soft metals, hard alloys & other types can also be marked accurately and precisely by laser machines. There is a wide range of applications from traceability, to personal customization of gift items, and much more!

Laser Marking and Engraving on Metals:

- Alloyed Steels

- Titanium

- Carbides

- Brass

- Stainless Steel

- Aluminum

- Hardened Metals

- Copper

- Silver & Gold

- Coated Metals

Function and Advantages of Laser Technology

Cost Efficient

- Direct marking does not increase costs for consumables (inks, chemicals, pastes, sprays)

- No need for handling and disposing of excess material

- No pre-or post-processing

- No tool-wear

Advantages of a laser

- The robust mechanics of laser systems have been designed for many years of intensive use with minimal servicing

Quick Marking, Great Output

- High speed marking with variable data (serial numbers, codes)

- Lots of marking options with no retooling

Advantages of a laser

- Simple, intelligent, and intuitive marking software

- Easily integrate contents from ERP files

Permanent Engravings

- Laser marking is permanent – abrasion, heat, and acid resistant

- Great for traceability and quality assurance

Advantages of a laser

- Product portfolio with matching fiber laser systems for any requirement

- Custom-built systems according to customer requirements

- Flatbed systems with processing areas of up to 1500 x 1250mm

Fine Tools

- Tiny, precise shapes can be marked with accuracy

- Marking processes can be combined to clean the material after processing

- Marking processes can be combined to provide a higher contrast

Advantages of a laser

- Ideal optics and beam performance thanks to high-quality components

- Camera-based component positioning for high precision and simplicity

Incredible Design Opportunities

- Virtually any design can be created with the laser

- You can create 1-point fonts and tiny shapes that are still clearly legible

- Complete freedom in design

- Photographs can be produced quickly and easily

Advantages of a laser

- DirectMark or JobControl software – laser marking or engraving directly from the graphics program make everything as easy as printing

Contactless Material Processing

- There is no need to firmly clamp down or fixate materials

- Achieve consistently good results

- Save time

Advantages of a laser

- Broad product portfolio with the right laser system for any requirement

- Highly accurate laser marking, even on your ‘first attempt’ thanks to camera-assisted positioning

Color Marking on Stainless Steel

- Produce colored markings on stainless steel

- Mark colored logos and graphics

Advantages of a laser

- Consistently mark in color with the MOPA laser

- Consult Trotec experts regarding color applications

- Multicolored annealing marking