Laser engraving for the military

The law requires laser engraving on military firearms for traceability — including the serial number and logo.

Variable-pulse fiber lasers (MOPA) produce deep engraving and surface marking with a superior finish. That‘s why they are so popular.

Laser engraving technology provides long-lasting results regardless of the material. However, steel and aluminum (anodized or painted) usually produce the best outcomes.

LASIT for the military

Our FlyCAD software can create any traceability code or logo and can even import them into a vector format. Contractors can easily handle different logos, codes, and layouts. LASIT also develops custom software with an integrated MES/ERP interface.

Besides all the advantages of the standard fiber laser, this new technology has pulse adjustment, which makes for cleaner, better-looking logos and designs.

Powerful suction system

Laser engraving generates dust. That’s why you must always have a suitable filtration system. LASIT decided to manufacture a system in-house, customizing it based on its 30+ years of experience in the industry.

Vision system for 2D and OCR code

At LASIT, we specialize in integrating systems that check the quality of alpha-numerical codes (OCR) or bi-dimensional codes (QR/DMC). All LASIT markers can be integrated with one or the other system or both.

Vision system for 2D and OCR code

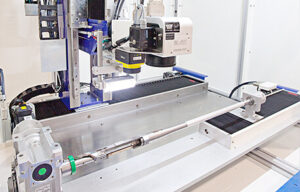

For laser marking long, cylindrical pieces, such as rifle barrels, we developed a rotary system with a motorized tailstock that can mark heavier items while rotating.

Our Advantages

| Sole supplier | No intermediary, from design to realization |

| Interface | PROFIBUS protocols, PROFINET and PROFIsafe |

| Integration | Integrations with MES / ERP systems |

| Industry 4.0 | Business database interaction for industry 4.0 |

| Vision system | Automatic centering, 2D code verification and grading, OCR recognition |

| Laser system | For every application and integration in production chains |