The FiberFly laser marker uses the most innovative ytterbium-doped active fiber technology and is the ideal solution for precision laser marking, micro-processing, and cutting metal and some plastic. We recommend Green or UV MOPA lasers for laser marking on plastic because it is more delicate.

Powermark FiberFly for integration is a robust, durable product, that works in any industrial environment. It can be used for laser marking: 2D codes, alphanumerical codes, one-dimensional codes, and logos.

Fiber lasers have a lifetime of over 100,000 hours of laser marking, and their operating independence makes these lasers extremely easy to control by PLC. Its size (rack format) is another significant advantage for anyone who needs to use this laser in a production line or a robotic cell. As with all LASIT laser markers, this one can be integrated into the line with Profibus, Profinet, or Ethernet/IP protocols.

To guarantee protection against network power surges or micro-outages, each FiberFly marker has a filter system, and a flexible stainless steel tube protects and guides the connecting wires. An additional steel shield protects the optical fiber against electromagnetic interference and electrostatic discharge for safe working conditions.

All our Laser Markers are qualified for Industry 4.0. LASIT supplies all the necessary technical materials and instructions for connecting the laser to the factory’s system at no additional cost. LASIT can ship this product in 48 hours.

Discover why our clients choosed us

MANFROTTO

ELECTROLUX

AMERICAN AXLE & MANUFACTURING

BERETTA

Fiber laser marking: how it works

INSTRUCTIONS FOR STAND-ALONE USE

In this mode, the laser operates without a command PC, and it can be integrated into production lines with limited space.

It does not require an operator interface, and installation is much faster.

- Generates serial numbers and dates automatically

- Remote control

- Updates operating content dynamically via TCP or RS232

- Loads the last process performed automatically on startup

- Automatically manages up to 9 mechanical axes with integrated encoder

- TTL (through the lens) vision system for an accurate preview

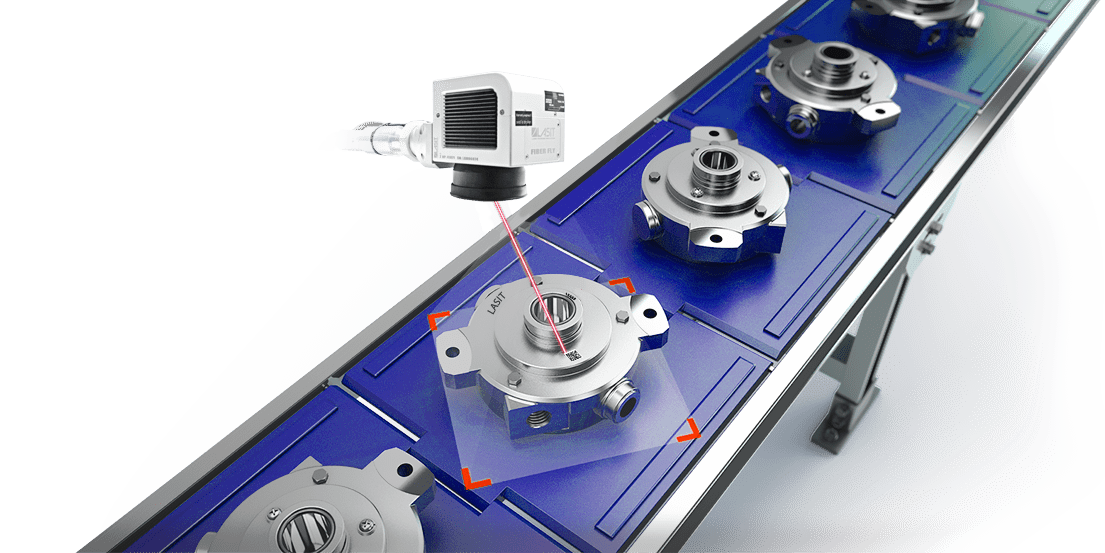

- On-the-fly laser marking

- 3D head for managing different focal lengths

MANAGE MULTIPLE LASERS WITH A SINGLE PC

As an alternative to FlyCAD, the FlyPowermark software with a fully customizable operator interface is available for automated environments. It can manage several data input modes, for example, access to the company factory system (database, web services, TCP/IP). It can potentially manage an infinite number of lasers, making it possible to design applications to command all the lasers on the line simultaneously.

- No limits to the size of the design

- Select the print layout manually or automatically from the barcode reader

- Remote loading and dynamic content updating via TCP or PROFINET

- Automatically manages up to 9 mechanical axes with integrated encoder

- Interfaces with inspection systems for DMC reading and grading

- On-the-fly laser marking

- 3D head for managing different focal lengths

Laser marking on metal

This is the most common laser for marking metal. It is most effective on: aluminum, steel, stainless steel, and titanium. Marking is permanent, precise, and high-contrast

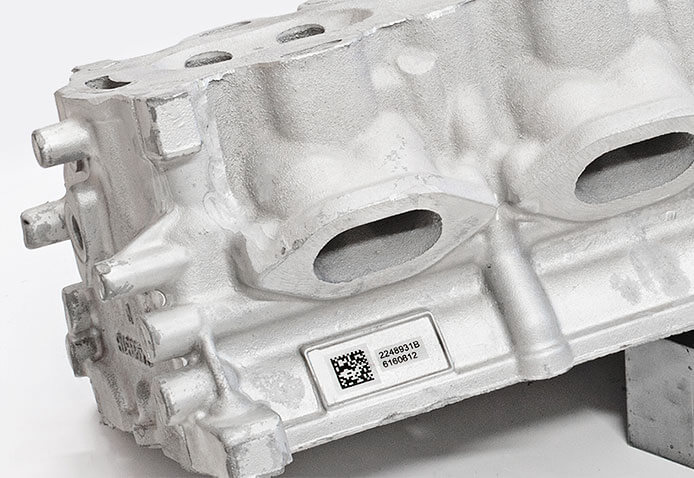

Marking on diecast

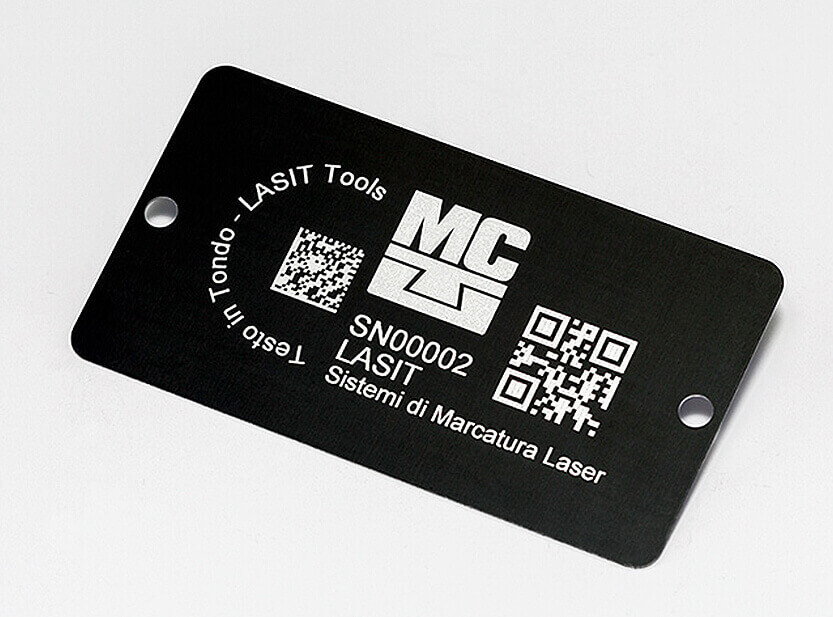

Marking on tools

Marking on tags

Marking on diecast

Marking on tools

Marking on tags

Cameras for reading and grading DataMatrix codes

In addition to the lateral vision system, LASIT equips its laser markers with the TTL vision system. This vision system is directly integrated into the laser scanning head and is perfect for validating (reading and grading) DataMatrix codes without moving the laser or the camera.

This is possible because the light reflected by the part is directed on the camera’s detector in the same exact path as the laser beam.

The integrated circular light offers a clear view inside the framed area, and the brightness can be adjusted.

There are two possible scenarios for DMC validation:

- If the marking is classified between A and B (based on AIM-DPM standards), the part is validated and proceeds along the production line.

- If the validation is lower than B, the marking is detected as NOK, and the part is rejected at the next station.

3-axis-head for 3D laser marking

The system is equipped with the 3-axis head for laser marking large, cylindrical, or irregular surfaces, which allows a constant focal elevation to be maintained.

Mechanically, it consists of a linear motor system, two X and Y rotary devices (allowing the laser band to be moved along the axis), and a third axis for focusing. The laser band passes through a scope equipped with a mobile lens that, in turn, is assembled on a linear traverse.

The software automatically adjusts the operation. This system allows the focal point of the laser to advance without it moving along the Z axis. Powermark Fiberfly can also be equipped with an Autofocus system, which allows the focal distance to be corrected automatically. It consists of a laser sensor integrated optimally in the LASIT software.

Technical Features

| Wavelength | 1064nm |

| Source | Ytterbium fiber |

| Frequency | Up to 5 MHz |

| Marking area | It depends on the focal point |

| Input/output | Standard I/O - Custom interface |

| Cooling method | Air or water cooled |

| Housing weight | 17.5 kg |

| Laser and scanner weight | 5.5 kg |

| Communications protocol | Profinet, Profibus, Ethernet, RS232 |

| Available power | 20, 30, 50, 100, 200 W |

Wavelength

1064nm

Source

Ytterbium fiber

Frequency

Up to 5 MHz

Marking area

It depends on the focal point

Input/output

Standard I/O – Custom interface

Cooling method

Air or water cooled

Housing weight

17.5 kg

Laser and scanner weight

5.5 kg

Communications protocol

Profinet, Profibus, Ethernet, RS232

Available power

20, 30, 50, 100, 200 W

| Focal | Marking distance (mm) | Marking area (mm) |

|---|---|---|

| EFL 100 | 150 ± 10 | 87 (61x61) |

| EFL 160 | 225 ± 10 | 140 (100x100) |

| EFL 254 | 325 ± 10 | 220 (150x150) |

| EFL 330 | 395 ± 10 | 290 (205x205) |

| EFL 420 | 500 ± 10 | 424 (300x300) |